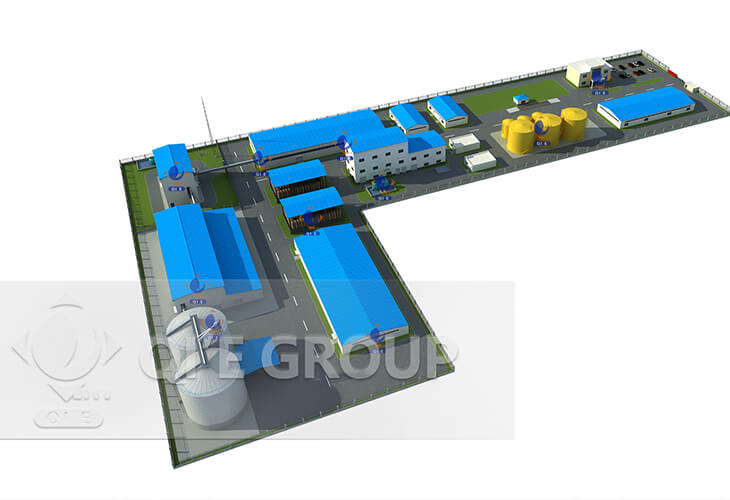

Coconut Oil Production line

Coconut oil production line, our company adopts physical pressing. The dried coconut is washed, dried, broken and softened; After that, the crude oil is obtained by pressing twice.

Coconut oil production line, our company adopts physical pressing. The dried coconut is washed, dried, broken and softened; After that, the crude oil is obtained by pressing twice.

-8.png)

Flow chart of coconut oil production line:

copra →cleaning→ drying →crushing→softening→ pre pressing → twice pressing →filteration → crude oil tanks → refined section → refined coconut oil

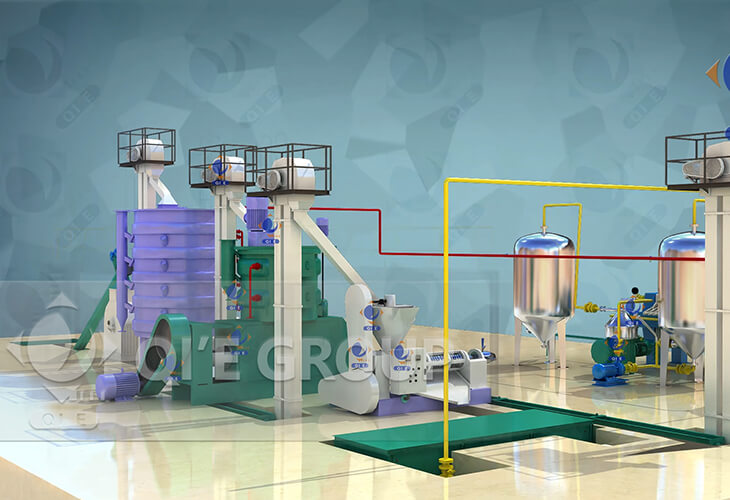

Pre-treatment and pre-press

Pretreatment and prepressing section is a very important section before extraction. It will directly affect extraction effect and oil quality.

(1) Cleaning: remove shell and brown skin and washing by machines .

(2)Drying: putting clean coconut meat to chain tunnel dryer ,

(3)Crushing: making dry coconut meat to suitable small pieces

(4)Softening:The purpose of softening is to adjust the moisture and temperature of oil, and make it soft.

(5) Pre-press: Press the cakes to leave oil 16%-18% in the cake. The cake will go to extraction process.

Press

Through two squeezes, Press the cake till the oil residue is about 5%.

Refinery

According to customer needs, we can supply continuous refining and semi-continuous refining equipment include degumming, deacidification, decolorization, bleaching and deodorization, in order to improve the FFA and the quality of oil, extending the time of storage.

Submit your enquiry,we will reply your quote within 24 hours.

Lianhua Street and Mudan Road,High-tech development zone, Zhengzhou City,Henan Province, China

Lianhua Street and Mudan Road,High-tech development zone, Zhengzhou City,Henan Province, China